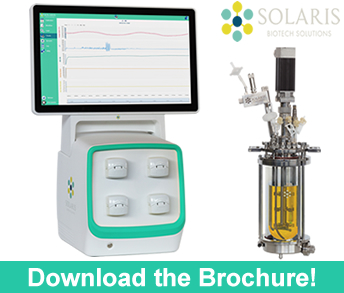

JUPITER Single & Parallel Fermenter & Bioreactor

Jupiter: Parallel control of up to 24 independent fermentations/cultivations, simultaneously!

The JUPITER platform from SOLARIS is a highly versatile and customisable fermenter/bioreactor. With several vessel sizes and designs available, anywhere from 2 to 10 L total volume, as well as multiple aspect ratios and thermoregulation designs.

One of the key benefits of this system is its scalability. With the Jupiter, you can keep adding more units, and still automatically manage up to 24, with the same controller.

Built with high quality components, this fermenter is available in two versions: jacketed (fully removable and cleanable) or single wall, with heating blanket and cooling finger (Jupiter SW).

JUPITER is fitted with a Process Control System based on a web-based (Linux) software Leonardo 3.0 and Siemens S7 1200 PLC. The HMI control panel (interface) is made through a very user-friendly PC 24” touch screen.

The system is designed for aerobic and anaerobic cultivations/ fermentations, closed aseptic operations. The control is based on a SCADA (Supervisory control and data acquisition) control system.

Parallel Means Smarter & Faster

The Leonardo 3.0 Software is intuitive & user-friendly. This smart controller was designed to provide a high level of automated management of the fermentation/ cultivation processes: batch, fed batch or continuous processes.

This software can be used for process development, which saves you time (and money) by taking a parallel fermentation approach. With the JUPITER you can carry out up to 24 independent fermentations/cultivations simultaneously & wirelessly!

Thanks to Modbus Digital Sensors, this system benefits from a robust communication protocol not susceptible to signal loss, as well as in-software sensor diagnostic information, parallel calibration/batch calibrations and more.

This means more mobility as users can access the JUPITER remotely, via PC, tablet or phone (with multi-level password protection) and be confident that connection to the running batch won’t be lost.

Main Features

- Up to 24 units managed with one HMI with innovative PARALLEL process control

- LEONARDO user-friendly software for a high level of automated management

- Different gas mixing strategies with up to 5 Thermal mass flow controllers (TMFC)

- Remote access via PC, tablet/smartphone

- Powerful & accurate brushless motor, from 1 to 2000 RPM

- Online absorbed Torques (Nm) and Power (W) measurements getting an indirect density indication of the culture broth

- Modbus Digital sensors

- LEDA safe sterile sampling system

- Safety pressure relief valve included in each unit

- Compact and modular PCS optimising benchtop space

- Additional parameter in modular external boxes for future PCS upgrade Including dCO2, cell density, weight, peristaltic pumps, etc

Applications

The JUPITER bioreactor is widely used in applications such as Education & Basic Research, Scale-up and Scale-Down Studies and Process Development & Optimization.

In addition to that, industries like Biopharmaceutical, Biofuels, Food Industry, Bioremediation, Bioplastic, Cosmeceutical & Nutraceutical also benefit greatly from using the JUPITER system.

Which Configuration Do I Need?

We will be happy to help you set up the JUPITER version you need to meet your application specific demands. Should you like to know more the JUPITER fermenter/bioreactor, please contact our Sales Team.

You can also see the other Fermenter/ Bioreactors we have available from SOLARIS on our website.

Help Me Build My Bioreactor! |