Manual cleaning versus machine reprocessing of laboratory glassware and utensils

A laboratory glasswasher makes reprocessing in a laboratory much safer, less prone to mistakes and therefore more reliable. Altogether, this helps streamline daily laboratory tasks and enhances overall standards of laboratory hygiene and safety.

Experiments and analytical procedures in laboratories require a reliable and consistent supply of thoroughly cleaned laboratory glassware. Reliable and accurate results can only be achieved when glassware and utensils are consistently clean, residue-free, and properly prepared. In other words, items must be free from impurities and any process chemicals previously used. Achieving this level of quality is uncommon with manual cleaning methods, which expose laboratories to the risk of compromising the standards required for analytical work and a robust lab utensil cleaning process.

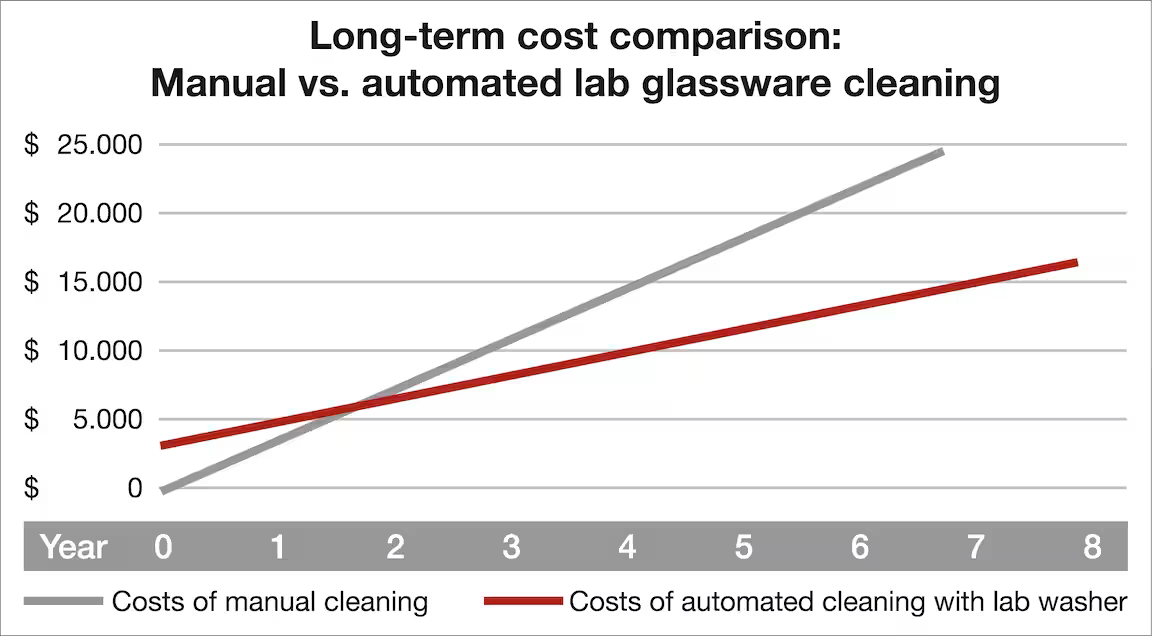

Even today, the manual cleaning of laboratory glassware remains widespread. The reasons for this are usually financial – many assume manual cleaning is cheaper than purchasing and maintaining a laboratory glasswasher. However, when the advantages and disadvantages are examined more closely, this assumption proves misleading.

Manual cleaning as a source of errors

Cleaning at the sink is not only messy and labour-intensive but also demands significant time and effort to achieve acceptable results. The time used by laboratory staff could be better spent on more productive tasks when reprocessing is automated. Moreover, achieving consistently high cleaning standards manually is challenging. Manual results depend on the individual performing the work, their experience, their method and the time they have available.

Manual cleaning also carries a high risk of damaging expensive laboratory glassware. Accidents when handling materials, cleaning tools and chemicals can significantly reduce the service life of glassware. At the same time, such conditions pose health risks to laboratory staff as they may inhale aerosols, come into contact with chemicals or suffer injuries from broken glass, all of which undermine laboratory hygiene and safety.

Machine reprocessing: an investment that pays off

Although the initial investment in a commercial laboratory glasswasher often raises concerns, many users overlook the long-term savings associated with machine reprocessing.

Time savings are the first major advantage: staff can focus on more valuable tasks, boosting efficiency. At the same time, they are freed from strenuous and unhealthy chores, which helps reduce sick leave and increase motivation and morale among laboratory staff. Speed is another significant benefit of using a lab washer. While manual cleaning and rinsing take approximately one minute per glass, 60 pieces of laboratory glassware can be automatically reprocessed in only 24 minutes, representing a time saving of around 59%.

Resource efficiency also plays a crucial role. Energy, water and process chemicals are precisely tailored to individual programmes to achieve excellent results without waste. Water consumption in an automatic process can be up to 63% lower than in manual cleaning. This not only benefits laboratory budgets but also considerably reduces environmental impact. Furthermore, machine reprocessing is much gentler than hand washing. The risk of scratching, etching or breakage is significantly reduced, extending the life cycle of reprocessed goods.

Everything speaks in favour of laboratory glasswashers

The higher initial investment required for a laboratory glasswasher pays off over time. Consistent, high-quality results alone justify the purchase. Additionally, lower labour costs, reduced use of electricity, water and process chemicals, and the extended life span of laboratory glassware all contribute to long-term financial benefits. The amortisation period naturally varies depending on cost structures and daily programme cycles, but average calculations indicate that the investment may pay for itself in under two years.

And, lastly, a laboratory glasswasher significantly increases safety, minimises errors and makes reprocessing in a laboratory more reliable. Overall, it greatly simplifies daily work and strengthens laboratory hygiene and safety at every stage of the lab utensil cleaning process.

Expert Support for your laboratory hygiene and safety from Lab Unlimited

To ensure a smooth transition from manual cleaning to machine reprocessing, Lab Unlimited provides comprehensive support throughout the entire lifetime of your laboratory glasswasher—from installation and commissioning to programme selection, chemical guidance, maintenance and ongoing technical assistance. As a trusted distributor of Miele’s laboratory solutions, Lab Unlimited is here to help you choose the right equipment and maintain the highest standards of laboratory hygiene and safety. If you would like to learn more about Miele products or need expert advice for your lab, reach out to us today for dedicated guidance and support.

|

To find out more: |