Product Categories

Spectrophotometry - UV or UV Vis Spectrophotometer?

What Should You Consider When Selecting UV or UV Vis Sensors?

Spectrophotometry is a method for measuring the amount of light absorbed by a type of molecule. Following its adaptation to online instrumentation, spectrophotometry has become a critical technique for monitoring and controlling both water and wastewater treatment facilities, while exhibiting increasing levels of accuracy and reliability by using online sensors.

The YSI IQ SensorNet family of ultraviolet (UV) and ultraviolet visible (UV Vis) sensors have fitted factory adjustments for specific wastewater treatment applications, increasing accuracy and reducing the requirement for recurrent calibration. Minimum maintenance is required due to its UltraCleanTM ultrasonic cleaning, no need for periodic calibrations, and no need to replace wear items like reagents or wipers. You can measure several parameters with only one sensor, for example nitrate, nitrite, total suspended solids (TSS), ultraviolet transmittance (UVT-254), chemical oxygen demand (COD), biological oxygen demand (BOD), total organic carbon (TOC) and several other carbon parameters.

These sensors are a significant investment for water and wastewater treatment facilities and provide several benefits to users. However, there are many factors to consider when choosing a sensor. To ensure you pick the correct sensor for your application, we highlight 5 questions to consider when selecting a UV Vis sensor.

Top 5 Questions When Selecting UV or UV Vis Sensors -

1. What Do I Want to Measure and Why?

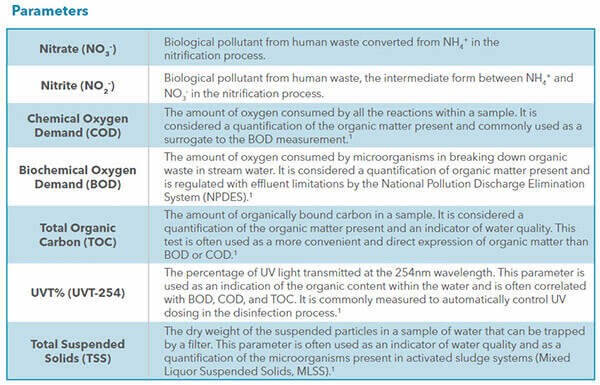

You will need to know the “what and why” before choosing a UV or UV Vis sensor. What parameters are you expecting to measure? What is the application? How will the sensor be used? Depending on the purpose, it may even be beneficial to monitor multiple parameters on a single sensor. The following are some of the most common applications for UV Vis sensors in wastewater treatment.

Nitrogen

The nitrogen parameters, nitrate and nitrite, are commonly measured in biological nutrient removal (BNR) applications. Nitrate can provide many opportunities for process optimisation, like efficient completion of nitrification, monitoring removal nitrate, control of carbon levels in anoxic zones, and ensure the compliance of effluents with nitrogen limits. Nitrite is less frequently measured as it is the intermediate stage of the nitrification process. Nitrite monitoring may be beneficial if a wastewater facility has an issue with nitrite accumulation or is utilizing a shortcut denitrification process.

Carbon

Carbon parameters also provide a variety of options for use within wastewater treatment. COD, BOD and TOC are common measurements for quantifying the carbon within a sample, with BOD and TOC being specific to organic carbon. In secondary treatment, COD can indicate the success of primary or secondary treatment or enumerate the amount of organic carbon present for a biological process which requires a carbon source (denitrification and phosphorus removal). Monitoring COD in the collection system or headworks of a wastewater treatment plant can help determine the source of heavy loads or provide early warning detection.

These parameters were impractical to be used until now, as they are known for requiring expensive or laborious lab procedures. However, the advent of online UV Vis sensors brought them to being used for process control and early warning detection applications, which would otherwise be unmanageable. Several possible applications for UV and UV Vis sensors are available, and in some cases, multiple parameters on a single sensor can be beneficial to the operator.

For instance, TSS is a common measurement within aeration basins indicating the concentration of microorganisms present (MLSS – mixed liquor suspended solids). By utilizing a sensor that includes TSS in combination with COD, the operator would have all information necessary for monitoring the food to microorganism ratio (F/M ratio). Monitoring several parameters with a single sensor can provide additional value by acquiring valuable data from a single sensor. We suggest you check the list of parameters available for each sensor when choosing a UV Vis sensor (Table 1).

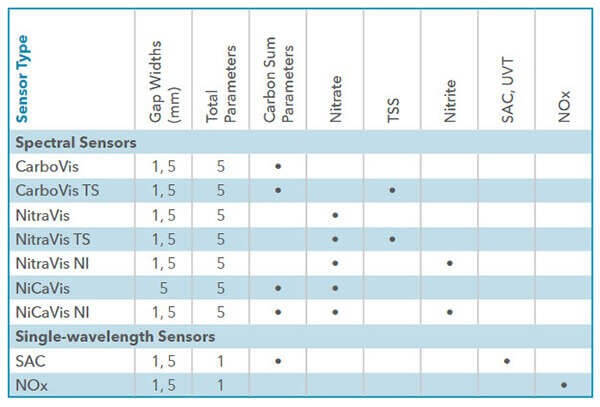

Table 1. IQ SensorNet UV Vis Spectrophotometer Sensor Types include CarboVis, NitraVis, NiCaVis,UVT-254, and NOx.

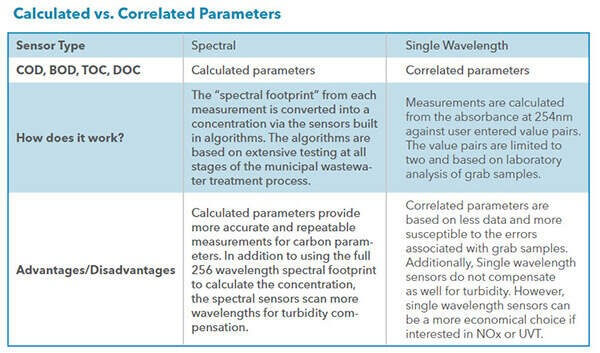

2.What’s the Difference Between Single-Wavelength and Spectral Sensors?

YSI, unlike other manufacturers, offers single-wavelength and spectral sensors where 256 wavelengths of UV and visible light are scanned per measurement to get a concentration of your desired parameter. These sensors measure absorbance at each wavelength to produce a ‘spectral footprint’, providing better precision and accuracy than single-wavelength sensors as absorption by a molecule occurs over a band of wavelengths, rather than just one. The additional wavelengths result in several benefits including more absorption data for each parameter, an array of wavelengths for turbidity correction, and even help detect different forms of organic molecules.

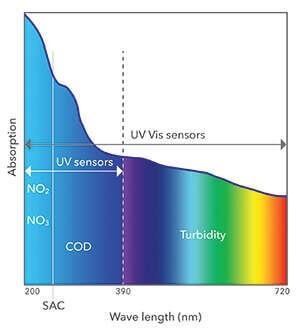

The 256 wavelengths scanned by UV Vis spectral sensors range from 200 to 720nm (Figure 1) across both UV and visible wavelengths, whereas the 256 wavelengths scanned by UV spectral sensors span between 200 and 390nm, allowing UV sensors to measure and differentiate between nitrate and nitrate. Nitrate and nitrite normally absorb at the shorter UV wavelengths (<250nm), while the organic molecules absorb most strongly at UV wavelengths between 250-350nm. Absorbance across 380 to 720 nm is from turbidity measured and corrected for with each measurement (Smith, 2019).

Figure 1. Ultraviolet and visible spectrum of light from 200-720 nm. Nitrate and nitrate primarily absorb UV light from 200-250 nm and organic molecules from 250-350 nm. Turbidity absorbs light from 380-720 nm.

However, there are two single-wavelength sensors that use the absorbance of one wavelength to determine the concentration of a particular parameter. The UVT-254 sensor (or SAC-254) measures the transmission or absorbance (%) of light at the 254nm wavelength. Ultraviolet light at 254nm is absorbed by organic molecules, making this sensor convenient for trending organics concentration within drinking water and wastewater. With the UVT-254 sensor, a correlated value of COD, BOD, and TOC can be reported with an accurate calibration and a second wavelength (550nm) is measured for turbidity correction. The NOx sensor measures the sum of nitrate (NO3-N) and nitrite (NO2-N) using a single wavelength which can be sufficient for monitoring nitrogen in some biological nutrient removal applications.

Even though single-wavelength sensors can provide valuable data and trending, they are limited in accuracy and repeatability compared to the spectral sensors. With the single-wavelength measurement and turbidity correction, these sensors may not detect some forms of organic molecules, cannot differentiate between nitrate/nitrite, and do not compensate for turbidity as accurately.

Both the single-wavelength and spectral sensors provide benefits, so which one is best for your application? The single-wavelength sensors can provide trending for organics or NOx at a reasonable price, and there are applications such as UVT-254 for UV disinfection, which specifically utilize single-wavelength sensors. As spectral sensors are calibrated to specific applications (influent, secondary treatment, effluent) and can scan 256 wavelengths, they provide higher accuracy, higher repeatability, and better correction for turbidity than single-wavelength sensors.

3. What's the Path Length and why is it important?

Path length or distance between the light source and detector (aka gap width) is significantly affected by the turbidity of the sample water. For that reason, UV Vis sensors usually have fixed path lengths and provide different gaps for specific applications.

The IQ SensorNet UV Vis sensors have 2 choices for path length: 1 mm and 5 mm (Figure 2). The 1 mm gap is for monitoring untreated wastewater and secondary treatment due to the high turbidity typical of these applications. The 5 mm gap is for monitoring treated effluent, wastewater with low turbidity, and can sometimes be adapted to some surface water or drinking water applications. Other manufacturers can have gap lengths of 10-50 mm gap lengths depending on the type of application. When choosing a YSI UV Vis sensor, choose the 701 style sensor for a 1mm path length (untreated wastewater or activated sludge) or the 705 style sensor for the 5 mm path length (low turbidity treated effluent).

Figure 2. YSI UV Vis sensors have two available gap lengths, 1 mm and 5 mm.

4. How will I mount my UV Vis Sensor?

You must carefully consider the size and weight of UV Vis sensors, as they are larger and heavier than other online sensors. The same applies to all online sensors where location and sensor mounting should be chosen based on safety and accessibility. It is vital to have plenty of space to work with the sensor as they will require occasional maintenance, therefore it needs to be easily accessible.

You must mount the sensor in locations that meet the required safety standards for hand railings and walkways. Along the same lines, the mount for UV Vis sensors should be easy to use and allow for easy manoeuvrability of the sensor. Finally, given the sensors can be relatively heavy, a robust and sturdy mount is required, especially for wastewater facilities with ragging issues.

The most common way to mount UV Vis sensors in wastewater is with immersion mounting, providing a direct measurement of the process water by submerging the sensor directly into a basin or stream. There are two options for immersion mounting YSI UV Vis sensors: a rigid mount or swing/chain mount. If you require a more robust solution, it is recommended to use a rigid mount as it fixes the UV Vis sensor to a metal pole and then mounts it to either a railing or wall. For typical immersion mounting applications, a swing and chain mount can provide numerous benefits such as better ease of use, as the sensor is suspended at the end of a chain and is simply raised or lowered into the basin with the chain. The swing arm extends the sensor out across the basin but can be easily accessed by swinging the sensor closer to the railing to remove the sensor for maintenance.

For clean water applications such as treated wastewater effluent, water reuse, or drinking water, a flow-thru cell may be the best option. Immersion mounting may not be possible in these applications due to the lack of a suitable location. With a flow-thru cell, the UV Vis sensor is wall-mounted, and the cell creates a chamber for water to flow across the optical window. Flow is continuously brought to the sensor for measurement and then drained. Whether you are using a YSI UV Vis sensor for clean water or dirty water, choosing the best mounting option for the application will ensure the sensor operates correctly and keeps the required maintenance to a minimum.

5. What are the Maintenance Requirements?

Although UV Vis sensors are light on maintenance and do not require reagents, they still need occasional attention for optimal operation. The YSI UV Vis sensors have the enormous benefit of requiring the least amount of maintenance compared to other online sensors. These sensors have built-in UltraCleanTM technology, a unique and automatic ultrasonic cleaning system. This system not only helps keep the measuring windows cleaner for longer, but it is also entirely internal to the sensor, so there are no seals or wipers to replace.

Because keeping a clean UV Vis sensor is vital to sensor performance, they often have very effective automatic cleaning systems, which reduces the overall time required to maintain the sensor. YSI offers two types of automatic cleaning systems: UltraClean which is built-in to all sensors and secondary air blast cleaning systems. The UltraClean ultrasonic cleaning system subtly vibrates the optical windows of the sensor, dislodging any solids building up. This technology has proven to be very successful in wastewater applications with high solids and is also utilized on YSI’s ViSolid (TSS) and VisoTurb (turbidity) sensors. The other option for automatic cleaning of YSI UV Vis sensors is an air blast system.

This system uses an air compressor to periodically force pressurised air over the optical windows, removing any solids that could disrupt the measurement. The YSI air blast system links directly to the sensor and is programmable within the controller to clean at a desired interval. Both automatic cleaning systems can keep sensors reading accurately for several weeks within wastewater applications.

Keeping a routine maintenance schedule ensures a clean sensor. Automatic cleaning systems are great for reducing overall maintenance time, but occasional manual cleanings are still required for optimal performance. Removing the UV Vis sensor from the process every two weeks for a manual cleaning goes a long way to reducing potential measurement issues. Manual cleaning is a quick 1-minute procedure that involves flushing out the measuring gap with clean water, applying a cleaning solution, polishing the lens with a soft cloth, and rinsing thoroughly.

Another aspect of maintenance is calibration and verification. Calibration for YSI UV Vis sensors is performed using lab reference samples, which are used to adjust the slope correlating the sensor’s raw signal to the concentration value. As previously mentioned, the spectral sensors are factory calibrated to specific applications, but it is possible to calibrate them to adapt the sensor’s measurements to the process water. The single-wavelength sensors can also be calibrated for their main parameters, but the correlated values (BOD, TSS, TOC etc.) must be calibrated to be accurate to lab measurements.

Calibration is performed as needed, such as when a sensor is first installed, moved to a new location, or the sensor is inaccurate to reference samples. YSI UV Vis sensors have a dual channel measuring system, in which an identical reference channel monitors and corrects for aging in the lamp or detector, preventing any potential calibration drift in the sensor. This makes routine calibrations unnecessary, however routine verification of the sensor measurement using a lab reference is recommended to ensure the accuracy of the sensor.

References

Smith, R. (2019). UV Vis Spectrophotometric Sensors for Wastewater Treatment Process Monitoring [White paper]. Retrieved February 17th 2019 from YSI, Inc: http://info.xylem.com/YSI-UV-Vis-Spectrophotometric-Sensors.html

APHA. (1995) Standard Methods for the Examination of Water and Wastewater, 19th edn. American Public Health Association, Washington, DC

UV-Vis Sensors from Lab Unlimited

If you have any questions about UV-Vis sensor and how it could benefit your organization contact one of our Environmental Sales Specialist.

Contact us Today! |