Product Categories

Using Fewer Flow Controllers for Increased Redundancy in Bioreactor Systems

Redundancy in bioreactor systems can be built to enhance the reliability and availability when the uptime is crucial. This redundancy in bioreactor systems leads to more uninterrupted hours to development and production of biologics; and when issues inevitably appear, redundant systems are able to compensate with minimal disruption to the process. This also eliminates risking system integrity or compliance.

The cost of a system often increases when building redundancies. However, in bioreactor systems incorporating redundant flow controllers can lower the overall system costs for both benchtop systems and pilot- and production-scale setups.

Increasing Flexibility for Benchtop Research with Redundancy

Small setups are often limited by budget and space as benchtop research makes pharmaceutical companies more cautious with biologics that have not yet been qualified, tested, and approved for mass use. This means that flexible equipment can serve multiple purposes is highly beneficial for research purposes.

It would be smart to consider a benchtop bioreactor that alternately flows oxygen and air, with the potential to also flow carbon dioxide and nitrogen. The traditional bioreactor systems require at minimum four mass flow controllers: one for each gas, and additional controllers if the flow rates are highly variable.

Instead use a single, flexible mass flow controller that alternate flows of any of the gases, individually or in combination, without the need for recalibration. The device can also operate across large range of flow rates (high turndown ratio). Therefore, it can provide the precise flows needed for controlled culture growth.

Having flexible flow controllers are highly beneficial in lab setups with multiple reactors working simultaneously, perhaps each growing a separate cell line to test. The traditional setups require a large number of flow controllers whereas flexible mass flow can be switched between reactors to flow gases as necessary.

The flexible controllers supply critical benefits when it comes to both money and space. The advantages include saving 4x cost on mass flow equipment and allows for more valuable bench space due to the significantly smaller bioreactor footprint.

Redundancy Allows Consolidation at Pilot- and Production-Scale:

Flexible controllers in larger-scale systems can allow the design to minimise the amount of flow lines as well as reducing the necessary spares inventory. The system is significantly easier to setup and more serviceable. It also decreases the potential for errors and increases the available uptime of the system.

This is achieved by using mass flow controllers with high turndown ratios. Typically, there would be separate flow controllers to control the low and high flows that are required for various stages of metabolic growth. However, a single mass flow controller with a large operating range can control both low and high flows.

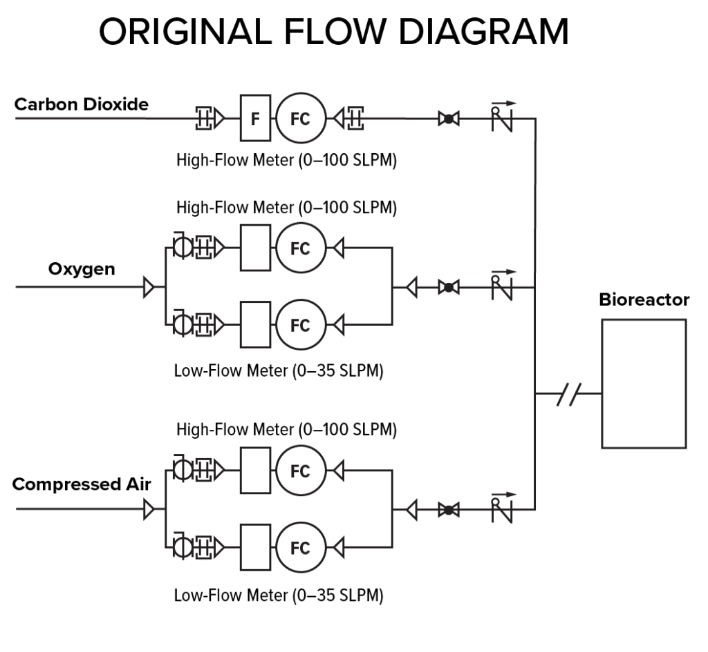

Original flow paths required separate meters for low and high flows.

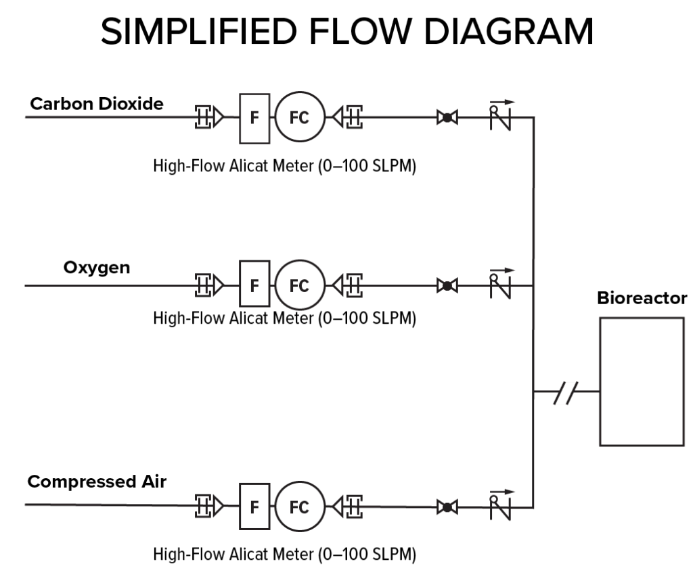

Simplified flow path used flexible flow meters with high turndown ratios to use a single flow meter for a wider range of flows.

Having fewer devices also means fewer potential points of failure. If a servicing is required or a failure comes about, all that is needed is a spare mass flow controller that can be inserted anywhere in the bioreactor system without configuration. Redundancy in bioreactor controllers therefore creates versatility created through the combination of high turndown and the capability to flow multiple gases without the need for recalibration. It also serves to maximise system uptime at the lowest possible cost.

Want to Know More?

If you want to find out more about how you can use flow controllers for increased redundancy in bioreactors, please contact a member of our sales team. They would be happy to help!

Contact us Today! |