Glassware - Ultimate Guide

Glassware is a necessary part of every lab

Depending on their usage and function in the lab, glass instruments come in a variety of forms, sizes, and sorts. Glassware is perfect for use in laboratories because it won't react with chemicals, ensuring that test results won't be tampered with. Glass is also transparent, making it simple to monitor and withstand high temperatures.

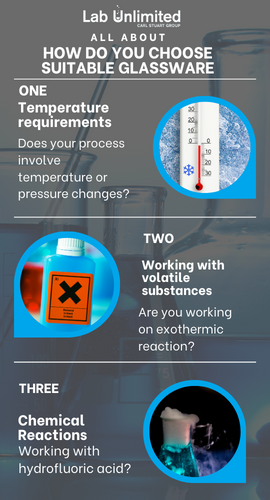

So how do you choose suitable glassware?

In order to select glassware that is compatible with your chemical process and your chemicals, you will need to determine its compatibility, otherwise, glassware can be damaged by the reaction of some chemicals with the glass.

- If your process involves temperature or pressure changes ensure that your glassware can withstand changes in temperature or pressure.

- When working with volatile substances that expand in the presence of heat, glassware won’t allow substances to expand and will result in an explosion.

- This can happens when sulfuric acid and water are combined in a measuring cylinder, and the heat from the reaction splits the bottom of the cylinder. In a measuring cylinder, never mix sulfuric acid.

- The glass is chemically harmed by hydrofluoric acid. Strong hot alkalis and hot phosphoric acid may both damage glass. Never put these chemicals in the glass.

Safe Handling of Laboratory Glassware

When working with laboratory glassware, there are some safety precautions everyone should take to avoid injuries. Here are some of them:

- Never carry necked laboratory materials such as bottles, flasks, and volumetric flasks by the neck.

- Never carry the beaker by holding its side surface.

- Always use both hands when carrying any glassware (put one hand under the glass for support).

- Appropriate gloves should be worn when there is a risk of breakage, chemical contamination, or thermal hazard. Always wear temperature protective gloves when working with hot or cold glassware.

- Avoid applying physical pressure to the glassware.

- Secure using clips and platforms/stands to relieve pressure, avoid overtightening the clamps.

- Use coated clamps to avoid glass-to-metal contact and do not use excessive force to tighten the clamps.

- Neck clamps should not be used as the sole support for containers larger than 500 ml.

- Grinded glass joints are made for a perfect fit and can sometimes stick. Never apply too much force to adherent glassware, it may cause the glass to break. You can lubricate the surfaces or use a Teflon sleeve.

- The hot air gun can loosen the sticking connections.

- Never heat or cool glassware unless designed for these processes.

- Round bottom flasks are best for boiling liquids.

- Never place hot glassware on a cold counter.

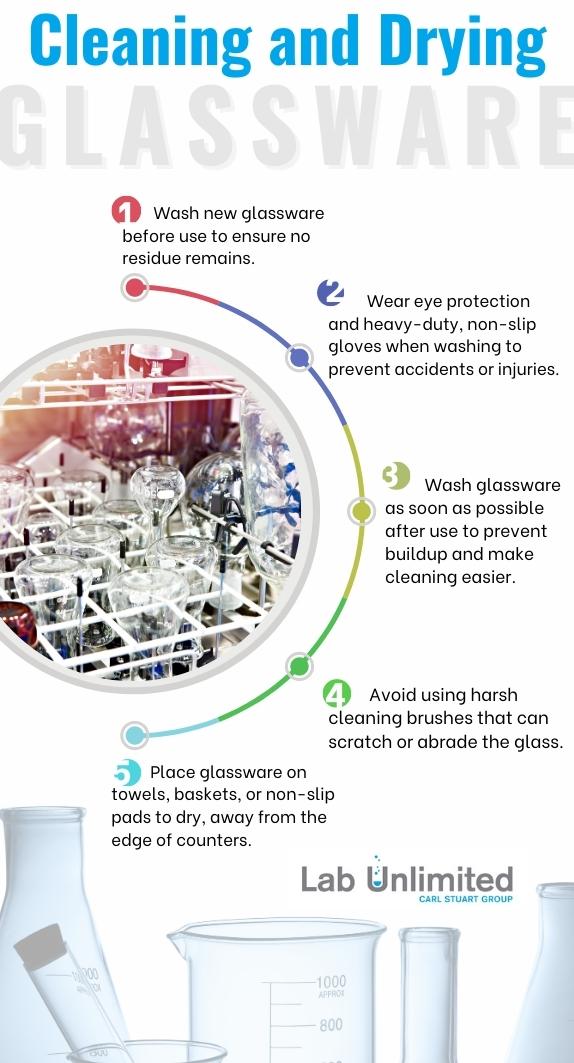

Cleaning and Drying Glass Equipment

We all know that cleaning glassware, as well as drying glass equipment is crucial because if not done properly, can tamper with our results. So here are some tips to keep in mind when cleaning and drying your glass equipment:

- When getting new glassware, you should wash and disinfect it before use to ensure that no residue remains on the glass.

- The glass must be physically clean, chemically clean, and in most cases sterile. To prevent any accidents or injuries you should always wear eye protection and heavy-duty non-slip and chemical-resistant gloves when washing glassware.

- It’s recommended that after every usage you wash your glass as soon as you can. It will be harder to clean if wait longer. If needed before washing allow the equipment to be submerged in soapy water, do not overload the sink and dishwasher, and keep glassware away from the edges of the sink. Additionally, we advise you to place rubber pads in the sinks to reduce the risk of damage and injury.

- When cleaning your glassware never use harsh cleaning brushes as they can scratch or abrade the glass. Always use a brush that is suitable to the task.

- While drying the glassware, place the items on towels, non-slip mats or pads, or a draining rack. And be sure to place them away from the edge of the counters. Large containers can be hung on hangers to dry.

- When cleaning the pipettes, place the pipettes with the tips down in a cylinder or long pool of water. A bottom pad made of cotton or glass wool will help keep the ends from breaking, make sure the pipettes are completely submerged in the water or disinfectant.

- We recommend that all staff should complete special training in the safe use of caustic cleaning agents before using chromic acid or other reactive solutions to clean glassware.

Steam Sterilisation and Autoclaving

To achieve effective sterilisation of glassware you should saturate it with steam. Before starting the process of sterilisation all contaminated materials must be cleaned, and the lids of the containers must be opened. For effective steam sterilisation all contaminated areas must be reached otherwise, microorganisms may not be destroyed. Be aware that chemicals can damage the product’s surface.

When working with plastics ensure they are vertical during autoclaving to prevent deformation.

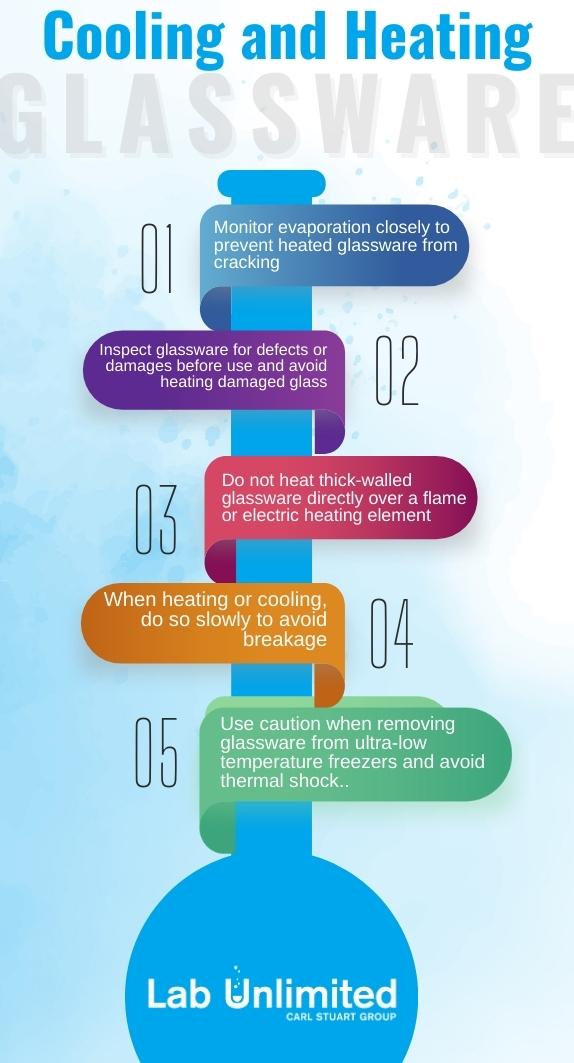

Cooling or Heating Glassware

When working with glassware you should be aware of temperature changes that equipment has to endure, so it’s advised that in the start you consult your glassware manufacturer to determine safe temperature use. Most glass materials can only be exposed to certain high and low temperatures, and when you use glassware outside of these ranges it can cause damage or breakage to the glassware. Although this damage may not cause visible damage to the glass immediately, it can cause breakage and injury later on.

- Always monitor evaporation closely. After evaporation has taken place, a heated vessel may crack. Do not place hot glassware on cold or wet surfaces as they may break with temperature changes.

- Inspect your glassware before usage to check for any defects or damages, never heat glass materials that are worn, cracked, nicked, scratched, or damaged.

- When working with thick- or heavy-walled glassware (eg bottles and jars) never heat them directly over a flame, the same when using glassware directly on electric heating elements.

- When heating glassware, it is critical not to look directly at it to avoid potential injury if the glass breaks.

- When cooling down your glassware do it slowly to avoid any breaking.

- Use caution when removing glassware from ultra-low temperature freezers (-70 to -150 C) to avoid thermal shock and cracking. For best results, immediately rinse the entire bottle under cold running water until dissolution begins. Never put bottles directly from the freezer into hot water baths.

- When using a Bunsen burner, the flame must touch the glass below the liquid level. A ceramic-centred wire gauze will spread the burner flame to provide more even heat. Always use a hotplate larger than the bottom of the glass is heated.

- Thick-walled glassware should never be heated on hot plates.

- When using a mixer with a heating function, make sure that only necessary settings are enabled , if you do not intend to heat, make sure the hot plate is NOT ON.

- Exothermic reactions, such as sulfuric acid dilution, should always be carried out with stirring and the reagents cooled, and suitable containers such as flasks should be used. Never use a measuring cylinder or a volumetric flask.

Working under vacuum or pressure

The walls of the vessel must be able to withstand pressure differences. If the container is not durable enough, the container may burst to avoid that you should always use a round-bottomed flask or heavy-walled bottles.

Glass materials designed for vacuum or pressure operations are graded according to certain pressure limits. To avoid any accidents never pressurise glassware that has not been designed for this purpose. In case glassware has been repaired and shows signs of defects or damage it cannot be used in vacuum systems.

When installing a vacuum system, protective measures should be taken:

- Place all vacuums behind a blast shield or in a hood.

- Don't forget to lower the hood flap.

- Always use suitable protective equipment: Safety glasses, face shield and gloves.

- Use polymer coated glassware whenever possible.

- If not found, cover bottles, and desiccators with tape.

Fitting of Glass Rods or Pipes

When setting up glass apparatus and sets you will be pushing glass tubes through a cork or stopper. With that comes a high risk of injury to your hands from breaking a glass tube, rod, or pipette. We recommend a few safety steps to avoid injuries and breaking glassware:

- Determine that the holes are the correct size for the glassware, never force the glass into place. To make it easier you can use a lubricant such as water, soapy water or glycerine on the bore and tube. Be aware not to use grease.

- Safety is in the first place so always wear cut-resistant gloves whenever possible and hold the glassware with a towel.

- When inserting glassware hold the glassware near the insertion point. Insert the glassware by turning it slightly. Be sure to hold the pipette near the tip you will insert. Do not use too much force, the glass may break and cause injury.

Heat Resistance

All glass materials are subjected to thermal stress during uneven heating or sudden temperature changes and the result is fractured glassware. Place your glassware in a cold drying cabinet or sterilizer and heat slowly. After drying or sterilization, the material should be allowed to cool slowly in the cabinet. Do not heat volumetric products on the hot plate.

Coated Glass Products

When dealing with hazardous and/or valuable materials, coated bottles are highly recommended. They feature the same technical specifications as clear and amber bottles. The coating on the body of the bottles is a special formulation that reduces impacts, acting like a protective glove and keeping broken parts together. This coating also prevents leakage, keeping the solution inside the flask body. It is highly transparent and can withstand temperatures up to 135°C for up to 30 minutes. Additionally, these bottles can be cleaned at 95°C and can be autoclaved repeatedly at 121°C. It's important to note that coated bottles should not be exposed to open flame.