Managing Viscosity to Improve Work Flows and Final Products!

These days, QC Labs are busier than ever! And why might this be? Because more new ingredients and formulations require testing for viscosity every day, along with the standard food products that require regular QC checks.

These days, QC Labs are busier than ever! And why might this be? Because more new ingredients and formulations require testing for viscosity every day, along with the standard food products that require regular QC checks.

In a competitive marketplace, more effort is put into getting new products out the door, so invariably the workload increases. But often the headcount does not grow to accommodate the added workload, or shortages in qualified candidates can mean that open positions can remain unfilled for some time.

Testing for viscosity is a “must do” requirement in most food companies since this predicts how the product will flow in use or when consumed. The success of a food product can hinge on the consistent flow behaviour (getting ketchup from a jar, spreading peanut butter) and appealing mouth feel (creamy yoghurt, smooth honey). Viscosity measurements during QC make all the difference in identifying materials that should be rejected because they don’t meet the required specification, and which may lose you customers if the sub-par batch were to reach the shelf.

When measuring viscosity, each test takes a few minutes to accomplish with a standard benchtop viscometer. The operator monitors the instrument and observes the data before noting down the number. But…

What if they could simply let the instrument run by itself and report a number, or series of numbers, automatically at the end of the test?

That would save the operator valuable time and allow other tasks to be handled while the instrument did its work.

Current lab viscometers (like the Brookfield Viscometer range ) make this possible because they include models that have a built-in clock and intelligent firmware that can perform calculations.

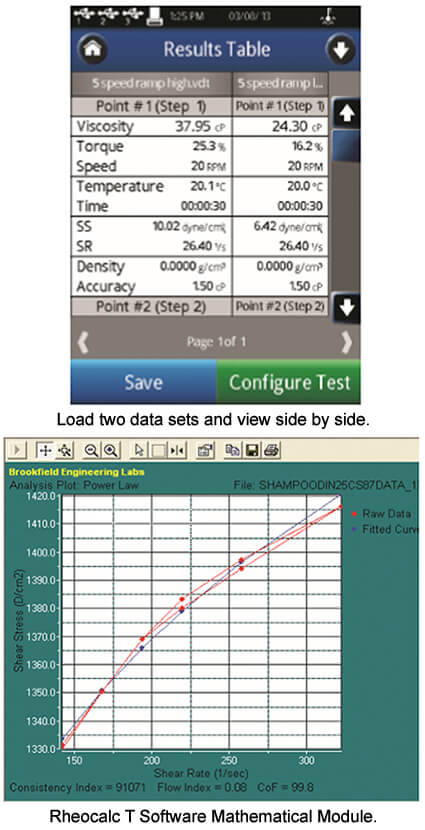

This means that the spindle can rotate for any amount of time predetermined by the operator. And the instrument can sample multiple viscosity data points and report each value separately or perform calculations and report an average value. Compare results on screen or overlay viscosity curves (selected models) to quickly compare products tested under the same conditions and evaluate consistency.

The improvements that the Brookfield Viscometer range can offer to the quality control of food items (and other products where viscosity is important) can save a company valuable employee time, reduced sample waste, and improved product quality. Define the QC limits for acceptable product data and control user access to method specifications to securely test and document quality.

For more detailed investigations use the Rheocalc T Software to evaluate parameters such as Consistency, Flow Index and degree of Pseudoplastic or Dilatant behaviour. These parameters are important for product development and matching, effects of ingredient substitution, product handling and perceived quality.

Take the initiative today and contact a member of our Sales Team to discuss how we can help improve your current viscosity testing.

Where Can I Find Out More About Viscosity?

Our full Brookfield Ametek Viscometer range is available on our website. If you have a need that is not covered in this range, please contact our Sales Team. You can also find more information on our Viscosity FAQ page.

Discover our Viscosity Range |

Discover Viscosity, Texture & Powder with Lab Unlimited!

Discover more about viscosity, texture, and powder analysis with Lab Unlimited.

Contact our team for technical support, guidance, or to explore our full range of Brookfield AMETEK instruments and viscosity standards.