Fusion Flow Technology by Alicat Scientific

Fusion Flow Technologies was made to assist with customer needs for industrial gas mixing applications. The skilled engineers have focused on novel applications and understanding the customers requirements to create a series of turnkey solutions that meet the various needs for research and industry.

Cost Effective and Flexible:

Fusion Flow gas mixers are custom built and designed specifically for your application. This makes them much more affordable and reliable than pre-mixed gasses as they typically have long delivery times and lack flexibility when it comes to in-house mixed gases.

Automate Your Gas Mixing:

The gas mixing systems from Fusion Flow Technologies are extremely flexible, traceable, and allow for easy automation of gas mixing processes. The systems enable you to mix up to 10 gases with user-friendly software.

The Solutions:

|

|

|

|

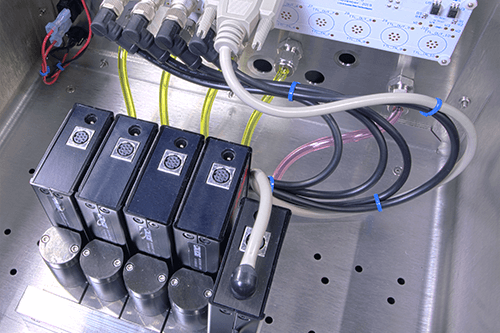

Modular Gas Mixing System The Fusion Flow™ modular gas mixing system was developed to integrate seamlessly into existing applications, or where a turnkey system isn’t feasible. Regardless of if you’re in research or highly customised, space-restricted processes, the module system can help define every facet of a highly focused, yet extensible system. |

Turnkey Gas Mixing System The Fusion Flow™ turnkey gas mixing system simplifies process automation in industrial applications. Each system can be custom-built to the customers needs based on your applications requirements. This results in an extremely compact single device solution to gas mixing. |

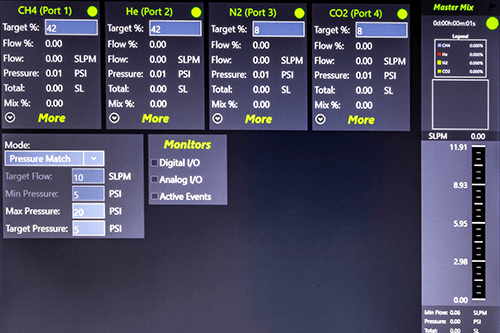

Fusion Flow™ Gas Mixing Software Precision counts when it comes to mixed gas. The Fusion Flow™ gas mixing software package was designed to allow precision mixing, rapid changes to mixes, and traceability measures for when conditions change. The software allows the user to control almost every parameter of the blending process. |

To Find Out More |

|

Available Ranges and Specs:

|

|

MXM |

MXM-PC |

MXM-SA |

MXM-PC-SA |

|

Flow range options |

0.1–100 SLPM per channel |

0.1–100 SLPM per channel |

0.1–5000 SLPM per channel |

0.1–5000 SLPM per channel |

|

Gas mixing channels |

Up to 6 |

Up to 6 |

Up to 10 |

Up to 10 |

|

Temperature ranges |

−10 – 60°C |

−10 – 60°C |

−10 – 60°C |

−10 – 60°C |

|

Maximum Input Pressure |

145 PSIG |

145 PSIG |

145 PSIG |

145 PSIG |

|

Outlet Pressure Range |

1–140 PSIG |

1–140 PSIG |

1–140 PSIG |

1–140 PSIG |

|

90 Preset Gases and Blends |

✓ |

✓ |

✓ |

✓ |

|

Fully Enclosed |

✓ |

✓ |

|

|

|

Portable |

✓ |

✓ |

|

|

|

Windows® Touch Panel PC |

|

✓ |

|

✓ |

|

Data Storage |

|

✓ |

|

✓ |

|

6-Button Control Panel |

✓ |

✓ |

✓ |

✓ |

|

Plug-and-Play |

✓ |

✓ |

|

|

|

Gas Mixing Software |

Optional |

✓ |

Optional |

✓ |

|

External Connectivity Board |

|

|

✓ |

✓ |

|

Digital and Analog I/O |

|

Optional |

|

Optional |

How does the Fusion Flow MXM precisely and reliably blend gases together?

The MXM system employs up to 10 Alicat Scientific high speed, precision, differential pressure-based mass flow controllers (MFC) to manage the flow rates of all constituent gases. A master ‘MixModule’ pressure sensing unit measures the outlet pressure of the resultant mixture, and continually sends flow commands to the subordinate MFCs. The user can run the mixer in one of three automated operational modes, which prioritize either the outlet pressure or the overall flow rate of the blended gases.

A fully customized internal plumbing network and multiplexing circuit board only require the user to connect the regulated feed gas sources, an outlet plumbing line, and electrical power cable before delivering freshly mixed gas. Various hard coded and adjustable self-checking routines constantly monitor the MXM’s performance, with the end goal to provide the desired gas blend under all operating conditions. A dedicated 6 button colour TFT control panel, and optional touchscreen PC let the user interact with the extensive control and automation settings which the MXM platform provides. Each Alicat Scientific mass flow controller can be used with up to 130 different on-board gases, which are selectable on the MXM machine. This allows the MXM to be used in other scenarios outside its original ‘as-sold’ configuration.

Download the Fusion Flow Technologies Brochure! |

Who can best take advantage of the MXM’s capabilities?

There are many industries and users that can take advantage of the MXM’s capabilities, such as:

- Laboratory managers who currently purchase expensive pre-mixed gas cylinders

- Companies rapidly developing new sensor technologies or calibrating existing ones

- R&D facilities needing to replicate innumerable natural and man-made gas mixtures

- Students, universities, hospitals requiring pressurized, modified atmospheres for glove boxes, cellular growth, or chemical process research

- Welding facilities looking to have on-demand, precision mixed shielding gas for all stations

- Burner/furnace manufacturers researching or using alternative combustion fuels

- Plasma based gas chromatography developers wanting a turn-key solution for their mixed gas needs

- Food suppliers packaging their products with exacting modified atmospheres

- Material engineers creating new compounds and processes with extreme consistency

- Laser equipment suppliers interested in reducing exotic gas waste

- Bulk gas suppliers dreaming of an alternative way to blend traceable mixtures without cumbersome techniques

- Gas analyser users or manufactures calibrating or characterizing their delicate equipment

To Find Out More |

|