Fusion Flow Gas Mixing Software

Fusion Flow Technologies have developed an advanced, rugged, and intuitive software that can easily manipulate every aspect of your gas mixing application. The current gas mixing software that is available on the market has a limited capacity and does not have critical abilities that are required for high performance gas mixing systems.

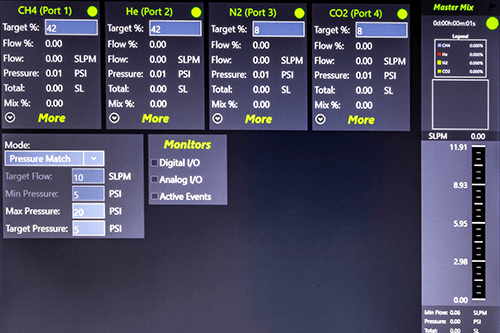

Fusion Flow™ Gas Mixing software displays individual channel data and overall gas mixture data always live for the user to monitor. There are several modes of operation for you to choose from, which are listed below. In all the operational modes, you decide the individual gas composition for each channel. These can be changed during the process, and the response times for a change is generally below 50ms.

Operational Modes:

Tank fill mode: This is the mode used for applications where a mixed gas fills a ballast tank. The maximum and minimum tank pressure can be chosen. The gas mixer will then fill the ballast tank and maintain the pressure between the limits while continuously maintaining the mix ratios in the ballast tank. This is useful in cases where usage of mixed gases varies over time, for example in MAP food packaging, welding, gas sensor, etc. assembly lines, a constant supply of gas is required at multiple locations. The gas mixer will continue to fill the tank until the upper limit and will shut off automatically if the usage amount decreases or becomes nil. This feature increases the efficiency of gas usage and means there is little to no wastage.

Constant flow mode: This mode is straight forward and most used in gas mixing applications. Set the gas mix ratios and the desired flow rate of the final mixture which the gas mixer will maintain all the time.

Pressure match: Fusion Flow Technologies is the only company that offers this operational mode. This gas mixing system allows you to control the pressure of the gas mixer and the process pressure. Many industries such as R&D, vacuum industry, laser industry, etc. need this feature and currently must spend exorbitant costs to obtain this capability.

You can switch from one operational mode to another with ease based on your requirements.

Maximize Your Efficiency:

The Fusion FlowTM Gas Mixing Software not only can change the basic parameters but provides several critical features to allow you to maximize your efficiency. One or a combination of the following features can be implemented to have full-fledged automation of the gas mixing process:

Gas Mix presets: Parameters such as gas mix ratios and flow rates/pressures that are typically used can be saved and called upon at any time. This minimises the risk of human-error by 15%.

Automation using presets: You can choose a gas mix preset to run for a specific period and change the preset and time on-the-fly, infinite times. You can interpolate between several gas mix presets by choosing time and ramp rates if constant change is required in your application.

Integrating with downstream/upstream process control instruments: Components like mass flow controller, mass flow meters, pressure gauges and pressure controllers external to the gas mixing system can be controlled with Fusion Flow™ Gas Mixing software.

Integration with third party equipment: Fusion Flow™ Gas Technologies allow you to integrate third part components. Depending on your requirements, the software can be used from a desktop remotely or on an industrial PC panel that can be offered.

With the Fusion Flow™ Gas Mixer, you can save all the gas mixing data that is needed for post processing. This vital data taken from the gas mixer can be used for the likes of quality audits and as the products are NIST traceable, you can be assured that the highest standards in the industry are being maintained.

Some applications will not need a complete software package to perform gas mixing and there are options available for this also. A TFT display to control the gas mixer can be used to set simple set points like gas mix ratios and flow rates that can keep your costs down.

Want to know more about the Fusion Flow Gas Mixing Software?

If you wish to know more about the Fusion Flow Gas Mixing Software, contact a member of our sales team today and they will be happy to help!

Contact us Today! |